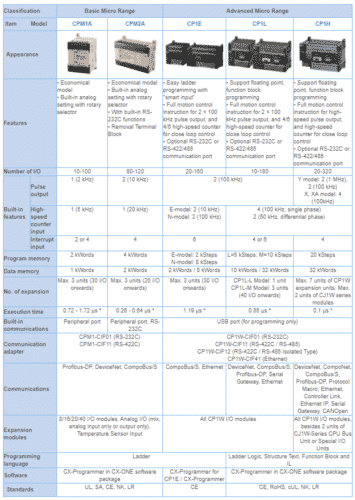

The criteria used in categorizing PLCs include functionality, number of inputs and outputs, cost, physical size, and in some cases the brand requirements from the client.

You can look as example the omron table for selecting a PLC.

Of these, the I/O count is the most important factor. In general, the nano is the smallest size with less than 15 I/O points. This is followed by micro types (15 to 128 I/O points), medium types (128 to 512 I/O points), and large types (over 512 I/O points).

Matching the PLC with the application is a key factor in the selection process. In general, it is not advisable to buy a PLC system that is larger than current needs dictate. However, future conditions should be anticipated to ensure that the system is the proper size to fill the current and possibly future requirements of an application.

There are three major types of PLC application: single-ended, multitask, and control management.

Single-ended

A single-ended or stand alone PLC application involves one PLC controlling one process. This would be a stand-alone unit and would not be used for communicating with other computers or PLCs. The size and sophistication of the process being controlled are obvious factors in determining which PLC to select. The applications could dictate a large processor, but usually this category requires a small PLC.

Multitask PLC application

Involves one PLC controlling several processes. Adequate I/O capacity is a significant factor in this type of installation. In addition, if the PLC would be a subsystem of a larger process and would have to communicate with a central PLC or computer, provisions for a data communications network are also required.

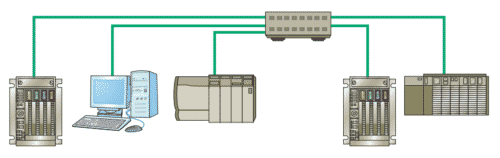

Control management PLC application

Involves one PLC controlling several others. This kind of application requires a large PLC processor designed to communicate with other PLCs and possibly with a computer. The control management PLC supervises several PLCs by downloading programs that tell the other PLCs what has to be done. It must be capable of connection to all the PLCs so that by proper addressing it can communicate with any one it wishes to.

Memory is the part of a PLC that stores data, instructions, and the control program. Memory size is usually expressed in K values: 1 K, 6 K, 12 K, and so on. The measurement kilo, abbreviated K, normally refers to 1000 units. When dealing with computer or PLC memory, however, 1 K means 1024, because this measurement is based on the binary number system (210 = 1024). Depending on memory type, 1 K can mean 1024 bits, 1024 bytes, or 1024 words.

Although it is common for us to measure the memory capacity of PLCs in words, we need to know the number of bits in each word before memory size can be accurately compared. Modern computers usually have a word size of 16, 32, or 64 bits. For example, a PLC that uses 8-bit words has 49,152 bits of storage with a 6 K word capacity (8 x 6 x 1024 = 49,152), whereas a PLC using 32-bit words has 196,608 bits of storage with the same 6 K memory (32 x 6 x 1024 = 196,608).

The amount of memory required depends on the application. Factors affecting the memory size needed for a particular PLC installation include:

- Number of I/O points used

- Size of control program

- Data-collecting requirements

- Supervisory functions required

- Future expansion