Safety has become an increasingly large factor in the working environment. The electrical industry, in particular, regards safety to be unquestionably the most single important priority because of the hazardous nature of the business. A safe operation depends largely upon all personnel being informed and aware of potential hazards. Safety signs and tags indicate areas or tasks that can pose a hazard to personnel and/or equipment. Signs and tags may provide warnings specific to the hazard, or they may provide safety instructions.

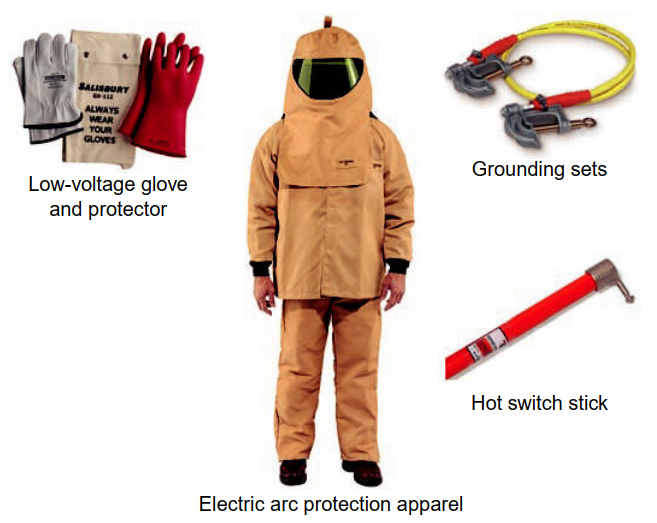

To perform a job safely, the proper protective clothing must be used. Appropriate attire should be worn for each particular job site and work activity.

With proper precautions, there is no reason for you to ever receive a serious electrical shock. Receiving an electrical shock is a clear warning that proper safety measures have not been followed. To maintain a high level of electrical safety while you work, there are a number of precautions you should follow. Your individual job will have its own unique safety requirements.

However, the following are given as essential basics.

• Never take a shock on purpose.

• Keep material or equipment at least 10 feet away from high-voltage overhead power lines.

• Do not close any switch unless you are familiar with the circuit that it controls and know the reason for its being open.

• When working on any circuit, take steps to ensure that the controlling switch is not operated in your absence. Switches should be padlocked open, and warning notices should be displayed (lockout/tagout).

• Avoid working on “live” circuits as much as possible.

• When installing new machinery, ensure that the framework is efficiently and permanently grounded.

• Always treat circuits as “live” until you have proven them to be “dead.” Presumption at this point can kill you. It is a good practice to take a meter reading before starting work on a dead circuit.

• Avoid touching any grounded objects while working on electrical equipment.

• Remember that even with a 120-V control system, you may well have a higher voltage in the panel. Always work so that you are clear of any of the higher voltages. (Even though you are testing a 120-V system, you are most certainly in close proximity to 240-V or 480-V power.)

• Don’t reach into energized equipment while it is being operated. This is particularly important in

high-voltage circuits.

• Use good electrical practices even in temporary wiring for testing. At times you may need to make alternate connections, but make them secure enough so that they are not in themselves an electrical hazard.

• When working on live equipment containing voltages over approximately 30-V, work with only one hand. Keeping one hand out of the way greatly reduces the possibility of passing a current through the chest.

• Safely discharge capacitors before handling them. Capacitors connected in live motor control circuits can store a lethal charge for a considerable time after the voltage to the circuits has been switched off. Although Article 460 of the National Electric Code (NEC) requires an automatic discharge within 1 minute, never assume that the discharge is working! Always verify that there is no voltage present.

Sources: Electric Motors and Control Systems-Frank D. Petruzella

Complementary Video