ARMANDO CHACON TERRAZAS

Electromechanical Engineer.

How I Got Started as Engineer.

Education

2011-2014

My journey as an engineer started when I began an associate degree in Mechatronics simultaneities with my High School Degree.

2014-2018

I decided to study Electromechanical engineering and during the university also I was involved on the ASME team as Electrical Designer where my principal project was to design an electrical solar car and we won two national challenges the first place: ASME’s e-Human Powered Vehicle and a Solar Challenge “Reto Solar Chihuahua”.

You can get more information here:

Experience

2018-Automation Technichian (Internship)

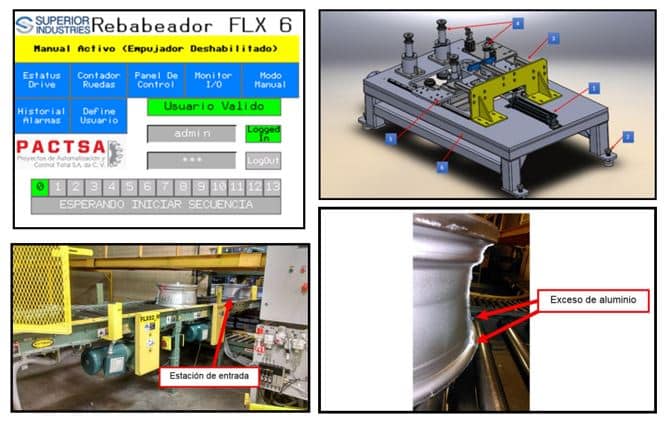

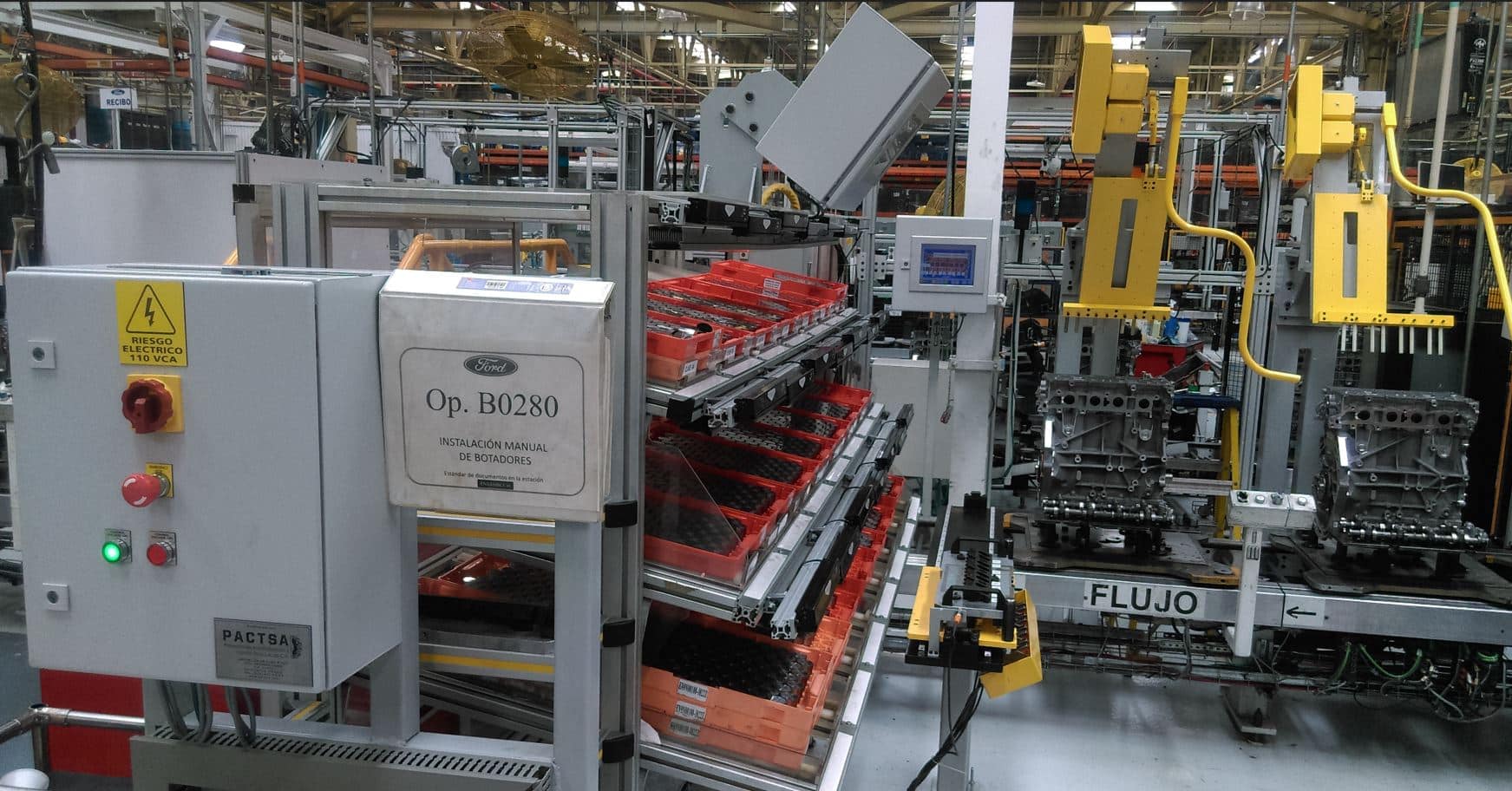

My first work was in PACTSA (Automation Company Solutions) located in Chihuahua, Mexico as Automation technician.

Here are shown some of the projects where I was involved:

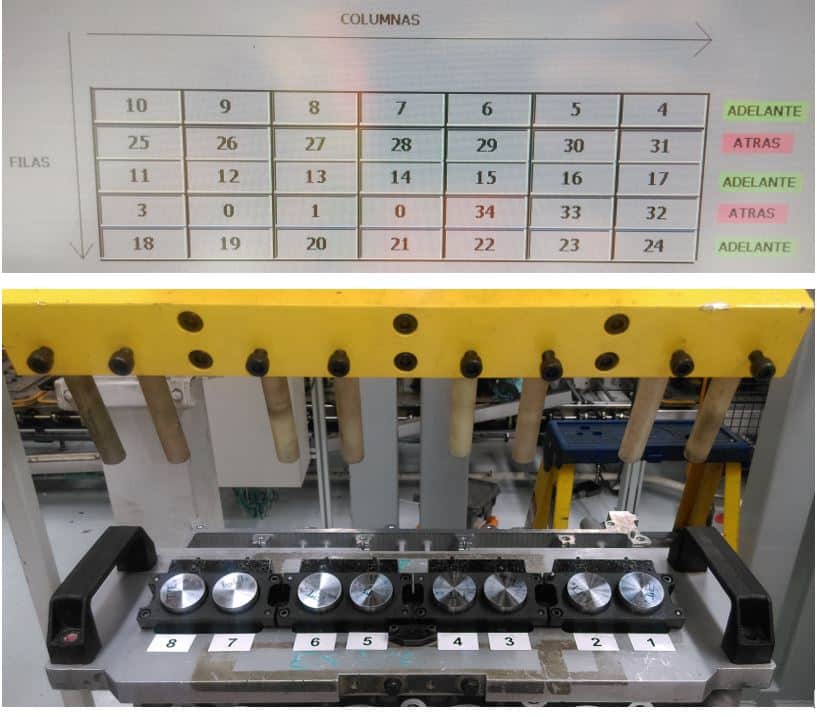

–Industrial machine for aluminum wheel manufacturer Superior Industries.

–Industrial machine for Ford Motor Company.

2019-2020-Testing & Automation intern USA

*This internship could be realized because I was the winner of the international program (EPEX) to realize an internship of one year in the United States. (Only best students selected).

My internship was realized in Safran (Aerospace Company before Zodiac Aerospace) located in New Jersey, United States.

You can know more about this in the next link:

http://www.dgest.gob.mx/academicas/impulsan-profesionalizacion-de-estudiantes-en-morelia-dp1

Here are shown some of the projects where I was involved:

Belmar Mockup Pokayoke – Standardization

Problem Statement: Potential risk of falling units from Mockups due improper girt bar attachment.

Solution: Add a pokayoke system with a PLC to ensure the girt bar is properly attached.

Grommet Machine User interface Improvement

Problem Statement: Current non ergonomic situation, the operator had to hold the packboard with his leg to be able to use both activation buttons.

Solution: Implemented a dual button activation within a hand-held system to Improved ergonomic and safety.

*Some of the projects where not included, but you can find the recommendation letter from my boss in Safran once finished the internship.

2020-2021

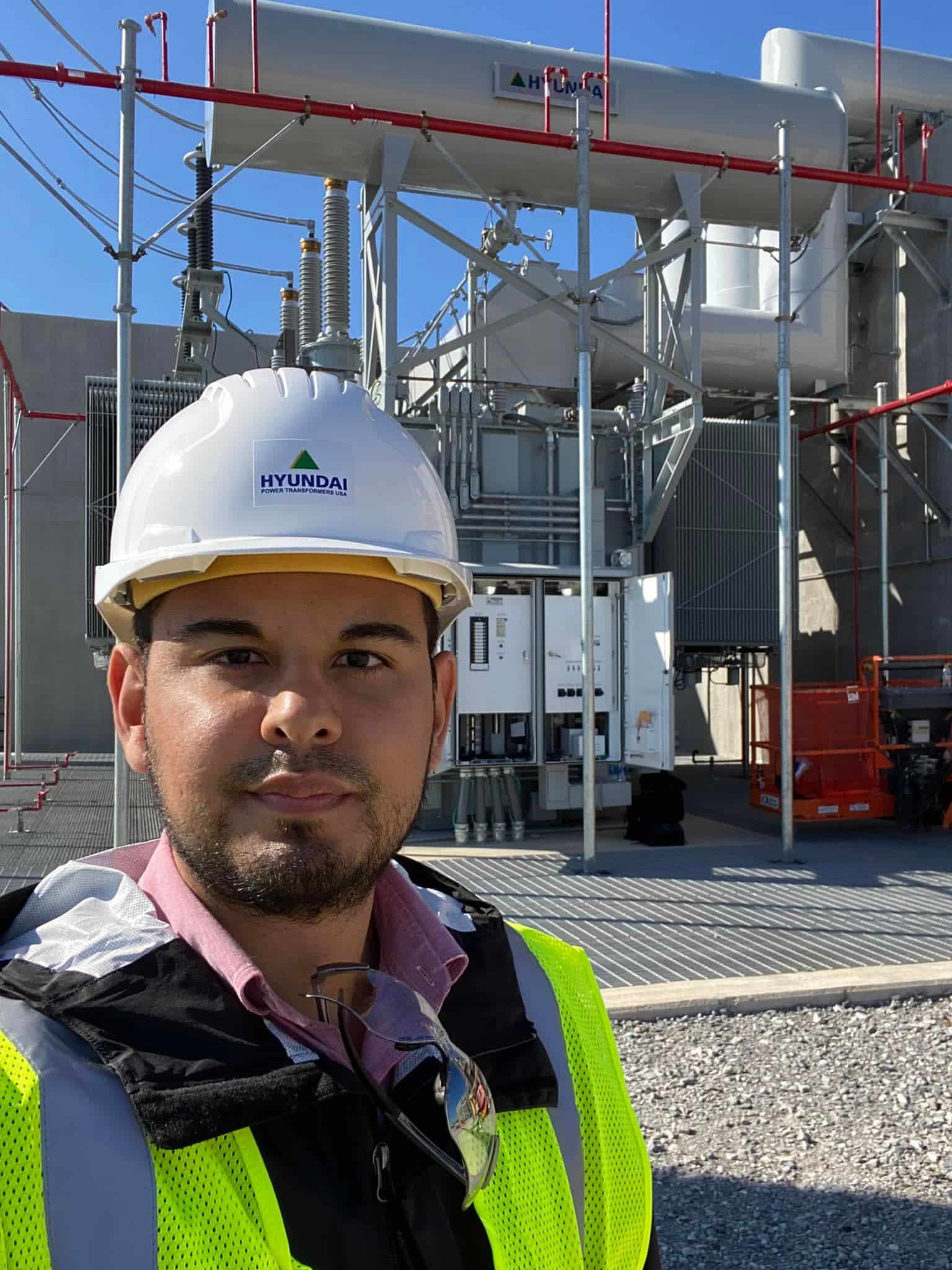

Control Design Engineer – Virginia Transformer Corporation.

Principal roles:

- Design of Electrical and Controls diagrams according international standards: UL508A, IEEE Std C57.148, CSA, IEC, NEMA, ANSI for Electric Transformers with AutoCAD for customer’s approval.

- Electrical calculations to create nameplates for electrical transformers following IEEE standards.

- Troubleshooting and technical support to customers, design teams, and production people.

- Analyzing costs and savings for electrical components to create a bill of materials for advance order.

- Design of shop floor instructions for production manufacturing & technical manual for the customer.

Principal roles:

- Design of Electrical and Controls diagrams for transformer designs following the UL508A, IEEE Std C57.148, CSA, IEC, NEMA, ANSI for Electric Transformers.

- Electrical calculations to create nameplates for electrical transformers following IEEE standards.

- Troubleshooting and technical support to customers, design teams, and production people.

- Analyzing costs and savings for electrical components to create a bill of materials for advance order.

- Design of shop floor instructions for production manufacturing & technical manual for the customer.

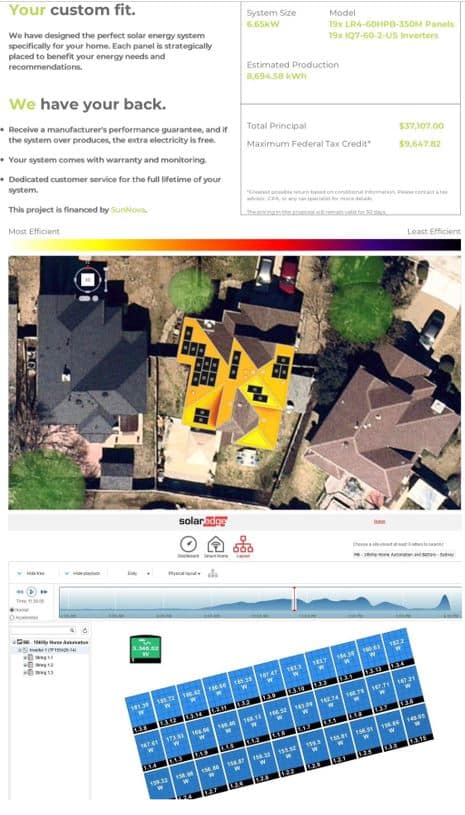

Principal roles:

- Create CAD and control diagrams for solar panel systems according to sales data sheet efficiency, and instruct and resolve doubts from technicians during installation.

- Analyzing costs and savings for electrical material.

*What is the page engineeringact?

While I was working in Hyundai I wrote the Control engineering Blog because does not exist to much documentation about the devices in a Electric Transformer, you can check by yourself some of my notes:

*Hello recruiter this page is created to verify with pictures & videos some of my work in this years.

If you make a double check to my resume you will find valuable certifications on the engineering market as:

- UL 508A MTR Qualification Examination v3

- Six Sigma Black Belt.

- Solidworks Associate (CSWA).

I invite you to see the pictures of my certifications mentioned on my resume.

The role of

Control Engineers

Control engineers are knowledgeable in overall plant systems and the interactions of processes.

They install and service a variety of systems including safety and security, energy delivery (hydraulic, pneumatic and electrical), communication, and process control systems.

They also install and service measuring and indicating instruments to monitor process control variables, monitor the operation of equipment and measure the characteristics of the material within a process. Control engineers work with final control devices such as valves, actuators and positioners to manipulate the process medium.

Control engineers inspect and test the operation of instruments and systems to diagnose faults and verify repairs. They establish and optimize process control strategies, and configure related systems such as Programmable Logic Controllers (PLCs), Distributed Control Systems (DCSs), Human Machine Interfaces (HMIs) and Supervisory Control and Data Acquisition (SCADA) systems.

Publications

I like to write and learn new things every day, most of the content that I support is in:

Control Engineering Blog